Wraps

- Portable Fire Equipment

- Portable Fire Extinguishers

- Mobile Fire Extinguishers

- Fire Extinguisher Vehicle Brackets

- Fire Extinguisher Cabinets & Covers

- Fire Extinguisher Servicing Tools & Consumables

- Fire Blankets

- Fire Hose Reels

- Fire Hydrant Landing Valves & Equipment

- Hoses, Nozzles & Adapters

- Lay Flat Hoses

- Hose Reel Tails

- Hose Nozzles

- Branch Pipes

- Storz Forged Aluminium Adapters

- Storz Cast Aluminium Adapters

- Storz Cast Aluminium Hydrant Couplings

- NSW/MFB Hydrant Couplings & Adapters

- CFA Hydrant Couplings

- QLD Hydrant Couplings

- BIC Hydrant Adapters & Couplings

- Washers

- Lay Flat Tools & Service

- Lay Flat Hose Cabinets

- Anti-Tamper Device

- Extinguisher Spare Parts

- Portable Extinguisher Parts

- Mobile Extinguisher Parts

- ABE 30 & 50kg Parts

- ABE 70 & 90kg Parts

- Purple K 30 & 50kg Parts

- Purple K 70 & 90kg Parts

- BE 30 & 50kg Parts

- BE 70 & 90kg Parts

- AFFF 30L & 50L Parts

- AFFF 70 & 90L Parts

- Alcohol Resistant 30L & 50L Parts

- Alcohol Resistant 70L & 90L Parts

- Fluorine Free 30 & 50L Parts

- Fluorine Free 70 & 90L Parts

- CO2 22kg Parts

- CO2 45kg Parts

- Wall Brackets

- Extinguisher Gauges

- Pull Pins

- Valve Stems & Valves

- Valve Seats & Washers

- Neck O' Rings

- Dip Tubes

- Springs

- Hoses

- Handles

- Portable Extinguisher CO2 Parts

- Nozzles, Valves & Adapters

- Rivets

- Mobile Extinguisher CO2 Parts

- Recharge Equipment

- Sirens

- Knapsacks

- Anti-Tamper Device

- AS1851 Testing Equipment

- Solo 365 Test Kit & Accessories

- Solo Kits

- Testifire Kits

- Smoke & Heat Heads

- TruTest Smoke Detector Sensitivity Kits

- Smoke Cans & Capsules

- Smoke Bombs & Smoke Pens

- Poles

- Battery Charger & Batons

- Removal Tools

- Accessories

- Universal Flame Detector Testers

- Scorpion Remote Detector Testers

- Digital Multimeters

- Speaker Testing Equipment

- Battery Function Testers

- Cyclone Canless Air Systems

- Digital Light Meters

- Ultrasonic Liquid Level Test Kits

- Extinguisher Service Tools

- Measuring Scales

- Fire Detection Systems

- Addressable Fire Alarm Systems

- Vigilant MX1 Addressable Panels

- MX1 Addressable Fire Panels

- AS1668 Controls and Gas Controls for MX1

- Addressable Detection & 850EMTK Programmer

- Addressable Modules and Field Devices

- Graphic Monitoring Software - XLG Client Server

- Vigilant Empty Cabinets & Battery Boxes

- IP Interface Networking

- MX Hazardous Detectors / Devices

- Documentation and Manuals

- FlameStop Addressable Fire Alarm Systems

- EST3X Addressable Fire Alarm Systems

- Vigilant MX4428 & F4000 Addressable Systems

- Simplex 4100ESi Fire Panels

- Vigilant MX1 Addressable Panels

- Emergency Warning Systems

- QE20 EWCIE and QE90 EWIS

- Occupant Warning Systems

- Evacuation Speakers

- Visual Warning Devices

- WIP Phones & WIP Cabinets

- Manual Call Points & Accessories

- VOX Speech Intelligibility Test Kits

- VESDA ASD Detectors

- Conventional Fire Alarm Systems

- Batteries

- Cable

- Smoke, Heat, Co Alarms & Accessories

- AS1851 Testing Equipment

- Ancillaries

- Power Supplies

- Miscellaneous Tools & Items

- Gas Panel Accessories

- Flame Detection

- Baseline Data & Termination Cabinets

- Stat-X Aerosol Fire Suppression

- OSID Emitters & Imagers

- Conveyor System Detection

- Anti-Tamper Device

- Addressable Fire Alarm Systems

- VESDA & FAAST FLEX ASD

- VESDA & FAAST FLEX Detectors

- VESDA Life Expectancy 2015

- Xtralis AS1851.2012 Maintenance

- VESDA LCD Programmer & High Level Interfaces

- VESDA-E Backward Compatibility Table – Firmware Versions

- Filters & Spare Parts

- VESDA Software

- Pipe and Fittings

- Automatic Air Purging System

- 19" Rackmount Configurations

- Gas Detection for VESDA

- VESDA Remote Displays

- Power Supplies

- VSM4 Configuration & Monitoring Software

- VESDA Documentation & Manuals

- VESDA Life Expectancy 2015

- Xtralis AS1851.2012 Maintenance

- VESDA-E Backward Compatibility Table – Firmware Versions

- VESDA Product Manuals & Data Sheets

- VESDA Technical Tips

- VESDA Maintenance & Troubleshooting

- VESDA Design & Commissioning

- VESDA Industry Documents

- VESDA Aspirated Smoke Detection for Impulse (Jet) Fans in Carparks

- VESDA Movies

- Smoke Bombs & Smoke Pens

- FAAST FLEX Documentation & Manuals

- Water & Mechanical

- Fire Sprinklers

- Valves

- Butterfly Valves cw Monitor Grooved

- Brass Butterfly Valves cw Monitor BSP

- Outside Screw and Yoke Gate Valve Grooved

- Outside Screw and Yoke Gate Valve Flanged

- Pump Connectors

- Swing Check Valves Grooved

- Alarm Valves - Grooved

- Waste and Test Valves

- Water Motor Alarm Gongs

- Retard Chambers

- Mini Ball Valves Gauge Cocks

- Lockable Ball Valves

- Brass Swing Check Valves

- Brass Spring Check Valves - Brass Spindle

- Brass Y Strainers

- Brass Gate Valves Threaded

- Pressure Relief Valves

- Sprinkler Control Valve Assembly’

- Wafer Check Valves

- Lugged Butterfly Valve c/w Lever Handle + Gear Operator

- Double Check Valves

- Globe Throttling Valves Grooved

- Globe Throttling Valves Flange

- Pressure Reducing Valves

- Bermad FP450 60 Tank Infill Valves

- Float Valves

- Solenoid Valves

- Brass Fittings

- Roll Groove

- Rigid Angle Pad Couplings

- Flexible Couplings

- Fast Connect Couplings

- Reducing Couplings

- Transition Coupling

- Standard Radius 90 Degree Elbows

- Short Radius 90 Degree Elbows

- Standard Radius 45 Degree Elbows

- Standard Radius 22.5 Degree Elbows

- Standard Radius 11.25 Degree Elbows

- Standard Radius Tees

- Short Radius Tees

- Reducing Tees

- Concentric Reducers GxG

- Concentric Reducers GxT

- End Caps

- End Caps with Eccentric BSP

- Mechanical Tees Grooved

- Mechanical Tees BSP Thread

- Grooved x Flanged Adaptors

- Grooved Hinged x Flange Adaptors

- Bull Head Tees Grooved

- Hydrant Elbows Grooved

- Grooved x BSP Adaptors

- HYDRANT LANDING VALVES

- FIRE HOSE REELS

- HOSES, NOZZLES & ADAPTORS

- Flexible Droppers

- Steel Pipe

- Gal Mal

- 90 Degree Elbows

- Tees

- 90 Degree Elbows MF

- Hex Nipples

- Sockets

- Square Plugs

- Unions Brass Seat

- Reducing Bushes

- 90 Degree Reducing Elbows

- Reducing Tees

- Reducing Hex Nipples

- Reducing Sockets

- Bull Nose Tees

- Service Tees

- Sprinkler MF Adaptors

- Table D Flange x BSP Thread

- 45 Degree Elbows

- 45 Degree Elbows MF

- End Caps

- Crosses

- Hangers

- 1 Piece Channel Clips

- 2 Piece Channel Clips

- Pear Bands

- Pear Bands HDG

- Nut Clips M10

- Nut Clips M12

- Mounting Plates

- Angle Brackets

- Beam Clamps

- Shallow Saddles

- Deep Saddles

- Twist Clips

- Wrap Around Pipe Clamps

- Purlin Clips

- Threaded Rod ZP

- Threaded Rod HDG

- Rod Joiners ZP

- Rod Joiners HDG

- Rod Cutters

- Channel and Angle

- Cantilever Brackets

- Medium Duty Saddles UN15

- Medium Duty Double Bolted Clamps UN16

- Medium Duty Yoke Clamps UN18

- Pipe Stand Clamps cw 50Nb Half Socket

- U Bolts

- 2 Piece Stainless Steel 316 Stand Off Bracket

- Mechanical Fasteners

- Monitor Switches

- Gal Steel

- Stainless Steel

- Consumables

- Valve Gaskets

- Flange Full Face Gaskets Table E

- Ring Gaskets

- Fibre Full Face Gaskets Table E

- Angus

- Bermad

- Chisolm

- Globe

- Grinnell Wormald

- Mather and Platt

- Matthew Hall

- Padde

- Reliable

- Shurjoint

- Star Model F Quell Guardian

- Tyco Central F

- Tyco Gem

- Tyco DV5

- Victaulic

- Viking

- Walter and CIE

- Waste and Test Kits

- Dorot Diaphragm

- Cometal Diaphragm

- Dobbie Dico Dual Booster

- Hydrant Landing Valves

- Pressure Gauges

- Traffolyte Signs and Stickers

- Tools

- Hydrant

- Hydrant Landing Valve Roll Groove

- Hydrant Landing Valve BSP

- Dual Hydrant Booster Roll Groove

- Dual Hydrant Booster BSP

- Single Point Booster Roll Groove

- Hydrant Booster Cabinets

- Booster H Patterns

- Dual Hydrant Risers

- Tank Suction Adaptor

- Dual Hydrant Booster Roll Groove High Pressure

- Quad Hydrant Booster Roll Groove

- Quad Hydrant Booster Roll Groove High Pressure

- Jacking Pumps and Accessories

- PPE

- Passive Fire

- Anti-Tamper Device

- Exit & Emergency Lighting

- Suppression Systems

- Flame Detection

- Conveyor System Detection

- Gaseous Suppression Systems

- Kidde WHDR Wet Chemical System

- Dry Chemical System

- Sentinel Vehicle Systems

- Stat-X

- Pressure Relief Dampers (PRD)

- Types of Kidde Gaseous Suppression (Clean Agent) Systems

- Coltraco - Ultrasonic & Safety Instrumentation

- Linear Heat Cable

- Fire Fighting Foam

- Passive Fire Equipment

- HYDRANT LANDING VALVES

- Cabinets

- Hardware & Fasteners

- Signage & Stickers

- Custom Engraved Sign

- Custom Printed Sign

- Custom Vinyl Cut Sign

- Signs and Labels

- Extinguisher Location Signs

- Fire Blanket Location Signs

- Extinguisher Charts/Cards

- Identification Signs

- Hose Reel Location Signs

- Fire Exit Signs

- Fire Door Signs

- Misc Signs

- First Aid Signs

- WIP Signs

- Offences Signs

- Alarm Signs

- Hydrant Signs

- Sprinkler Signs

- Fire Signs

- Pressure Test Stickers

- Extinguisher Pictographs

- Extinguisher Labels

- Water & Mechanical

- Pipe Markers

- Engraved Signs

- Hydrant Signs

- Hose Reel Signs

- Fire Hose Reel & Fire Signs

- Hydrant Pump & Valve Signs

- Sprinkler System Signs

- Fire Alarm Panel Signs

- Gas System Signs

- EWIS Panel Signs

- Electrical Signs

- Hazardous Signs

- Custom Block Plans

- Customised Signs

- Fire Safety Door Signs

- Cabinet Signs

- Commonly Used Signs

- CO Fire Detectors Installed Engraved Signs

- Signs for VADs and VWDs

- Vinyl Cut Lettering

- Block Plans & Evac Plans

- Snap Frames

- Cabinet Stickers

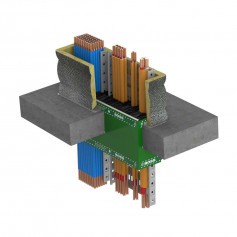

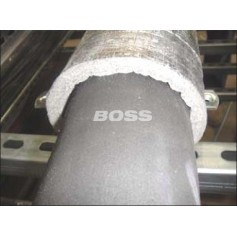

UniWrap

BUW-25

- Universal length for versatility and ease of installation

- Can provide fire rating for up to 35 x 100mm diameter pipes in a single roll

- Can be used on plastic/PVC pipes as well as insulated or lagged metal pipes

- High performance through high expansion rate

- Halogen free, contains no asbestos, ceramic, mineral fibres and is environmentally friendly

- Causes no known effects to plastic pipes, plastic cables, sheathing o r metallic components

- Tested on uPVC, PP, MDPE + PE up to 200mm diameter

Availability date:

- Universal length for versatility and ease of installation

- Can provide fire rating for up to 35 x 100mm diameter pipes in a single roll

- Can be used on plastic/PVC pipes as well as insulated or lagged metal pipes

- High performance through high expansion rate

- Halogen free, contains no asbestos, ceramic, mineral fibres and is environmentally friendly

- Causes no known effects to plastic pipes, plastic cables, sheathing o r metallic components

- Tested on uPVC, PP, MDPE + PE up to 200mm diameter

Downloads

TECHNICAL DATA SHEETS

CATALOGUE

SAFETY DATA SHEETS

Technical Details

- Width (mm) : 60

- Box Quantity : 1

- Density : 1.3kg per meter cubed

- Fire Rating : 2 Hour

- Single Units : Yes

Product Information

UniWrap® is an intumescent composition based on elastomeric thermoplastic polymers, binders and designed to provide high volume expansion and pressure seal. The product is fir e tested to multiple international Standards giving a f ire resistance of up to 4 hours, including EN1366 - 3 to - /120/120.

The pipes tested include PVC, Polypropylene, MDPE, HDPE, and HPPE up to a size of 200mm diameter pipes through concrete / blockwork floors and walls.

Benefits

- Tested in Block Wall, Concrete and Masonry.

- Tested in Concrete Floors.

- Tested in large service openings up to 250 x 150mm.

- Tested with Plastic Pipes – PVC, Polypropylene, MDPE, HDPE and HPPE.

- Causes no known effects to plastic pipes, plastic cables, sheathing or metallic components.

- Contributes to Green Building.

- Shelf life of 5 years.

- Suitable for wall and floor installation.

- The product is based on a thermoplastic composite and is therefore non - toxic.

- Halogen free, contains no asbestos, ceramic, mineral fibres and is environmentally friendly.

- Not affected by fungus, vermin or rodents.

- Remains flexible between - 40oC to +130oC, long life and is easy to use.

Specification

| Pipe Diameter | 28mm, 32mm, 55mm, 63mm, 75mm, 82mm, 90mm, 110mm, 125mm, 160mm or 200mm |

| Width (Nominal) | 60mm |

| Thickness (Nominal) | 4mm up to 63mm, 6mm up to 110mm & 10mm thereafter |

| Density | 1.3 kg/m³ |

| Volume Expansion at 300°C | 25 times |

| Fire Resistance | 2 hours |

Installation

- Ensure the aperture for the pipe size has adequate annular gap for UniWrap® to be installed. Insert the pipe into the aperture.

- Using the measurements on the side of UniWrap ® box, cut the UniWrap® to the correct length to wrap fully around the pipe. Check the UniWrap® Configuration table for the number of layers required, depending on your pipe size.

- Wrap the UniWrap® around the pipe, securing to itself via the double sided tape. For a simpler installation ensure the double sided tape does not stick the UniWrap® to the pipe itself.

- Place additional layer(s) of wrap around the pipe if required, depending on your pipe size.

- Secure again with adhesive tape.

- Push the UniWrap® into the annular gap between the wall opening and the pipe. Adjust the position of the wrap so that the edge is central within the wall or floor surface.

- Seal over the top of the annular gap with FireMastic - 300 Sealant to a depth of 5mm. Smooth the finish with a small trowel or by hand. FireMastic - 300 can be cleaned up with water.

- Maintain record of installation.

FlameStop 2024 Hard Copy Catalogue Now Available - FlameStop TV Episode 45

FlameStop 2024 Hard Copy Catalogue Now Available - FlameStop TV Episode 45  FlameStop TV Bloopers Edition No: 3

FlameStop TV Bloopers Edition No: 3  Emergency Door Alarm - FlameStop TV Episode 44

Emergency Door Alarm - FlameStop TV Episode 44  Fire Detection in Lift Shafts - FlameStop TV Episode 43

Fire Detection in Lift Shafts - FlameStop TV Episode 43