Manufacturer & Wholesaler to the Fire Industry

Portable Fire Equipment

AS1851 Testing Equipment

Fire Detection Systems

VESDA & FAAST FLEX Detectors

Exit & Emergency Lighting

Suppression Systems

Fire Fighting Foam

Water & Mechanical

Passive Fire Equipment

HYDRANT LANDING VALVES

BATTERIES

CABLE

Cabinets

Hardware & Fasteners

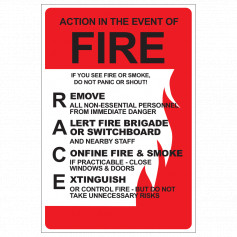

Signage & Stickers

Pro Audio / Public Address

Understanding TAN-09: What Australia’s Guidance on Lithium-Ion Battery Fires Really Says

Understanding TAN-09: What Australia’s Guidance on Lithium-Ion Battery Fires Really Says  Electromagnetic Door Holders & Electric Strikes – FlameStop TV Episode 51

Electromagnetic Door Holders & Electric Strikes – FlameStop TV Episode 51  North Brisbane Branch is Now Open

North Brisbane Branch is Now Open  Protecting Cold Storage Facilities using VESDA ASD – FlameStop TV Episode 50

Protecting Cold Storage Facilities using VESDA ASD – FlameStop TV Episode 50